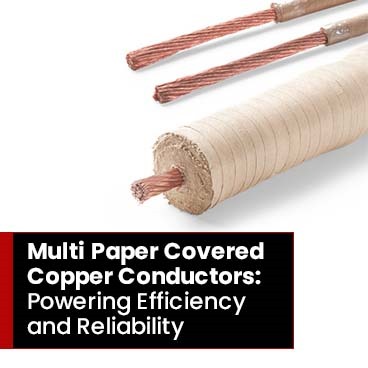

In the intricate realm of electrical engineering, transformers play an indispensable role in the transmission and distribution of electricity. At the heart of these transformative machines lies a crucial component that often goes unnoticed but is absolutely vital for their functioning – the Multi Covered Copper Conductors (MPCC). These conductors are the lifelines that ensure efficient power transfer and distribution within transformers.

Their primary purpose is to provide a reliable pathway for electrical currents, ensuring seamless energy flow within the transformer systems. These insulated cables consist of a copper conductor at their core, which serves as the conduit for electricity, enveloped in multiple layers of different types of insulation. The insulation not only protects against electrical leakage but also contributes to the mechanical robustness of the cable.

Critical Parameters for Evaluation

When considering the purchase of Multi Paper Covered Copper Conductor cables for transformer applications, several critical parameters warrant thorough evaluation to ensure optimal performance and longevity:

- Insulation Material and Quality: Different insulation materials offer varying degrees of electrical and thermal performance. The choice of insulation material depends on factors such as operating temperature, voltage levels, and environmental conditions. The quality of insulation is paramount as it directly influences the cable’s ability to withstand electrical stress and prevent short circuits.

- Insulation Thickness and Layering: The insulation thickness and the number of layers determine the cable’s dielectric strength and overall durability. A well-layered insulation system enhances the cable’s ability to withstand high voltage differentials and mechanical stress.

- Conductor Material and Size: Copper is the preferred choice of conductor material due to its excellent electrical conductivity. The conductor’s cross-sectional area (gauge) plays a pivotal role in determining the cable’s current-carrying capacity and resistance.

- Thermal Endurance: Transformers often operate in demanding thermal environments. Thus, the cable’s ability to withstand elevated temperatures without compromising its insulation properties is crucial for long-term reliability.

The importance of quality in Multi Paper Covered Copper Conductor cables cannot be overstated. These cables serve as the arteries of electrical energy within transformers, making their reliability and efficiency pivotal. Here’s why quality should be a paramount consideration:

Safety and Reliability: Subpar-quality cables can compromise the safety of personnel and the overall integrity of the transformer system. Quality cables ensure insulation integrity, minimizing the risk of short circuits or electrical leakages.

Longevity: High-quality cables are designed to withstand the rigours of transformer operation over extended periods. They exhibit superior resistance to degradation from temperature fluctuations, electrical stresses, and environmental factors, thereby extending the lifecycle of the transformer.

Performance Consistency: Quality cables maintain consistent electrical performance, reducing the likelihood of unexpected power disruptions or efficiency losses within the transformer. Vidya Wires stands as a premier choice for Multi Paper Covered Copper Conductor cables due to its unwavering commitment to excellence and innovation.

Here’s why Vidya Wires shines as a supplier of MPCC conductors:

- Customized Insulation Solutions: Vidya Wires tailors insulation solutions to meet specific customer requirements, ensuring optimal performance even in demanding applications.

- Cotton Braid Insulation: The use of cotton braid insulation adds an extra layer of mechanical protection, enhancing the conductor’s durability.

- Dot Glue Application: The application of dot glue in the final layer prevents any loosening of multiple insulation layers, ensuring long-term reliability.

- Printed Identification: Each cable comes with printed identification along with the size and specifications, simplifying installation, maintenance, and troubleshooting processes.

- In-House Paper Slitting Facility: With the availability of in-house paper slitting machines, Vidya Wires maintains meticulous control over the manufacturing process.

- Diverse Insulation Options: From KRAFT to KREPE, NOMEX, MICA, POLYESTER, and even TUP + NOMEX, Vidya Wires offers a comprehensive range of insulation options to cater to diverse operational conditions. Additionally, thermally upgraded options further expand the scope of applications.

Diverse Insulation Options for an Unparalleled Performance

The insulation plays a crucial role in conductors as it dictates the ability of the conductors to withstand the demanding conditions within transformers.

Vidya Wires takes insulation to the next level by offering an impressive array of options tailored to various operational scenarios. From traditional materials like KRAFT and KREPE to advanced choices like NOMEX, MICA, and POLYESTER, the spectrum of insulation options available ensures that every transformer’s unique needs are met.

For applications requiring exceptional thermal endurance, NOMEX insulation stands as an excellent choice. Its remarkable resistance to high temperatures and excellent dielectric strength make it a go-to option for transformers operating in demanding environments. On the other hand, MICA insulation shines with its ability to withstand not only elevated temperatures but also mechanical stresses, making it suitable for transformers exposed to both heat and physical strain.

POLYESTER insulation, known for its exceptional electrical properties and moisture resistance, finds its place in transformers dealing with fluctuating environmental conditions. This insulation type safeguards against moisture-related deterioration, ensuring consistent performance over time. Furthermore, the (Thermally Upgraded paper) TUP + NOMEX option showcases Vidya Wires’ commitment to innovation by combining the benefits of both materials for enhanced performance in extreme conditions.

In a world where transformers are tasked with increasingly complex challenges, having a range of insulation options at one’s disposal is indispensable. Vidya Wires recognizes this necessity and offers not only a diverse selection of materials but also thermally upgraded options that push the boundaries of performance. Whether it’s withstanding extreme temperatures, resisting mechanical stress, or combating moisture, Vidya Wires’ insulation choices empower transformers to operate with unparalleled reliability and efficiency.